Jun 12, 2025

Articles

Jun 12, 2025

Articles

Jun 12, 2025

Articles

12 Best Practices to Design Product Packaging [+Pro Tips]

Martin Ramirez

Martin Ramirez

Martin Ramirez

In 2025, the global packaging market is projected to reach $508.37 billion, growing at a compound annual growth rate (CAGR) of 7.2%.

With this growth, the importance of effective product packaging continues to rise.

In this article, we’ll dive into 12 product packaging best practices and the role of artwork validation in ensuring packaging compliance.

Let’s begin!

What is Product Packaging and Why Is It Important?

Product packaging is the process of creating the exterior of a product to protect, contain, and present it to consumers in a visually appealing manner.

The design must also clearly convey important information, meet regulatory compliance standards, and be adaptable to different consumer needs, all while supporting sustainable practices.

➤ This includes:

Adhering to Legal Requirements: Ensure packaging meets necessary regulations for ingredient disclosures, safety warnings, and other mandatory information.

Labeling Standards: Adhere to industry-specific guidelines for clear and accurate labeling, including product information and relevant certifications.

Regulatory Compliance: Ensure packaging complies with relevant industry regulations (e.g., FDA, EMA, CLP) to avoid legal issues and ensure safety.

In addition to meeting regulatory requirements, the importance of packaging design is also reflected in the following aspects:

Brand Identity: Packaging reflects your brand’s values and personality, helping consumers recognize and connect with your product.

Protection and Preservation: It ensures the product’s safety during transport, storage, and handling, maintaining its quality.

Consumer Experience: Good design improves usability and enhances the unboxing experience, encouraging repeat purchases.

Marketing Appeal: Attractive packaging can stand out on shelves or online listings, influencing buying decisions and boosting sales.

Pro tip

To stay ahead of regulatory changes, leverage Signify's automated regulatory monitoring to monitor evolving regulations and standards that impact your products.

With real-time regulatory updates and clear, actionable insights, Signify helps you focus on the changes that matter most to your business, allowing you to adapt proactively before any changes are enforced.

Packaging Types, Levels, and Functions

Product packaging is typically categorized into three levels:

➤ Primary Packaging:

This is the immediate container that directly holds the product, representing the smallest unit of sale.

Examples include a soda bottle, cereal box, or blister pack, as well as labels on medicine vials or pet food pouches.

➤ Secondary Packaging:

This packaging groups one or more primary units together, typically for shipping, display, or marketing.

Common examples include corrugated cartons (e.g., holding six cans of soda), shrink-wrapped multipacks, and retail display boxes.

➤ Tertiary Packaging:

Used for bulk storage and transportation of multiple secondary packages, tertiary packaging includes items such as pallets, stretch wrap, and large crates.

Its primary purpose is to ensure protection and efficiency during logistics and warehousing.

Key Packaging Functions (the 3 Ps)

Packaging serves three essential functions: protection, preservation, and presentation.

Each function plays a crucial role in maintaining the product’s integrity and appealing to consumers:

Protection: Packaging must safeguard the product from physical, chemical, and biological damage during handling and shipping. Under US cGMP (FDA 21 CFR 211 Subpart G), written procedures are required for inspecting and testing all packaging materials before use.

Preservation: Packaging helps extend shelf life and maintain product quality. This includes barrier properties and moisture control.

Presentation: Packaging design visually conveys the brand and product message, drawing consumer attention with colors, graphics, typography, and shape.

12 Best Practices to Design Product Packaging

Branding and Visual Identity

Effective packaging should reflect your brand’s values, reinforce your message, and make a lasting impression.

Let’s see how you can affect it.

1. Ensure Consistency Across Packaging

Packaging consistency across all products ensures a unified brand identity that customers easily recognize and trust.

This reinforces your brand message and fosters familiarity, a key factor in achieving long-term brand success.

➤ Why it matters: Consistent branding across all packaging ensures a cohesive, recognizable identity that strengthens customer loyalty and drives brand recognition.

➤ How to implement:

Use the same brand colors, logos, and fonts across all packaging elements.

Ensure that the product name, key benefits, and company logo are clearly visible and consistently placed.

2. Organize Information with a Clear Hierarchy

Clear and well-organized packaging enables consumers to locate the most important information about the product quickly.

Prioritizing visual clarity and structure ensures that essential details are easily visible and comprehensible.

➤ Why it matters: It simplifies decision-making and improves the shopping experience.

➤ How to implement:

Organize visual elements so that key information, such as the product name and claims, are the first things consumers notice.

Keep the design minimalistic, using clean layouts and ample white space to avoid clutter.

3. Engage Consumers with Multi-Sensory Design

Multi-sensory packaging elements enhance consumer engagement by stimulating more than just the visual senses.

This creates a richer experience, allowing customers to connect emotionally and build a memorable brand interaction.

➤ Why it matters: Multi-sensory elements such as textures, scents, or interactive features deepen the connection between the product and the consumer.

➤ How to implement:

Add textures, such as embossing or soft-touch coatings, to enhance the tactile experience.

Utilize scents, such as scratch-and-sniff features, or incorporate interactive elements like QR codes to enhance the digital experience.

4. Test and Personalize Designs for Engagement

Personalized packaging and market testing enable brands to understand what resonates most with their target audience.

It enables more targeted engagement and produces packaging that genuinely appeals to the consumer.

➤ Why it matters: Testing different design variations and personalizing packaging helps brands connect with their audience on a deeper, more meaningful level.

It also boosts customer engagement and loyalty by offering a unique experience.

➤ How to implement:

Run market tests with different design variations (colors, fonts, shapes) to see which resonates best.

Use digital printing for personalized labels or limited-edition packaging that engages customers.

Compliance & Labeling

Packaging must adhere to both local and international standards to ensure safety, transparency, and proper information.

Let’s explore it further.

5. Comply with Regulatory Labeling Requirements

Regulatory content includes mandatory label elements that ensure your product complies with relevant laws and regulations.

This is especially crucial for industries such as food, cosmetics, and pharmaceuticals, where non-compliance can result in significant legal and financial repercussions.

➤ Why it matters: Accurate, compliant labeling ensures your product adheres to legal standards and helps avoid fines, recalls, or legal challenges.

➤ How to implement:

Adhere to local regulations, such as FDA guidelines in the U.S. or FIC requirements in the EU, to ensure ingredient lists, allergen warnings, and nutritional claims are accurate.

Regularly update labels to comply with evolving regulations and regional requirements.

Pro tip

Signify streamlines regulatory tracking, risk assessments, and product labeling validation across various industries.

With its AI-driven automation, Signify streamlines complex tasks, reduces compliance burdens, and ensures your processes remain precise and up-to-date with evolving global regulations.

Whether you’re in manufacturing or quality assurance, Signify enhances operational transparency, allowing you to focus on delivering quality products.

6. Display Hazard and Warning Labels Correctly

Packaging for products in regulated industries must include specific hazard and warning labels to protect consumers.

These labels help inform customers about potential risks associated with the product, particularly in the cases of pharmaceuticals, chemicals, and tobacco.

➤ Why it matters: It ensures that your product complies with legal safety requirements.

➤ How to implement:

Include required hazard symbols and safety phrases for chemicals and pharmaceuticals.

Follow tobacco-specific regulations for graphic health warnings in the United States and the European Union.

7. Localize Labels for Different Markets

Labeling must be appropriately localized to ensure it meets the legal requirements of each target market.

It should be accessible to a diverse consumer base and comply with regional laws regarding language and information.

➤ Why it matters: Besides requirements, it fosters trust with customers by providing them with clear, understandable information.

➤ How to implement:

Translate labels into the required languages for each target market, following local legal requirements.

Be mindful of language nuances and ensure all required warnings and instructions are clear.

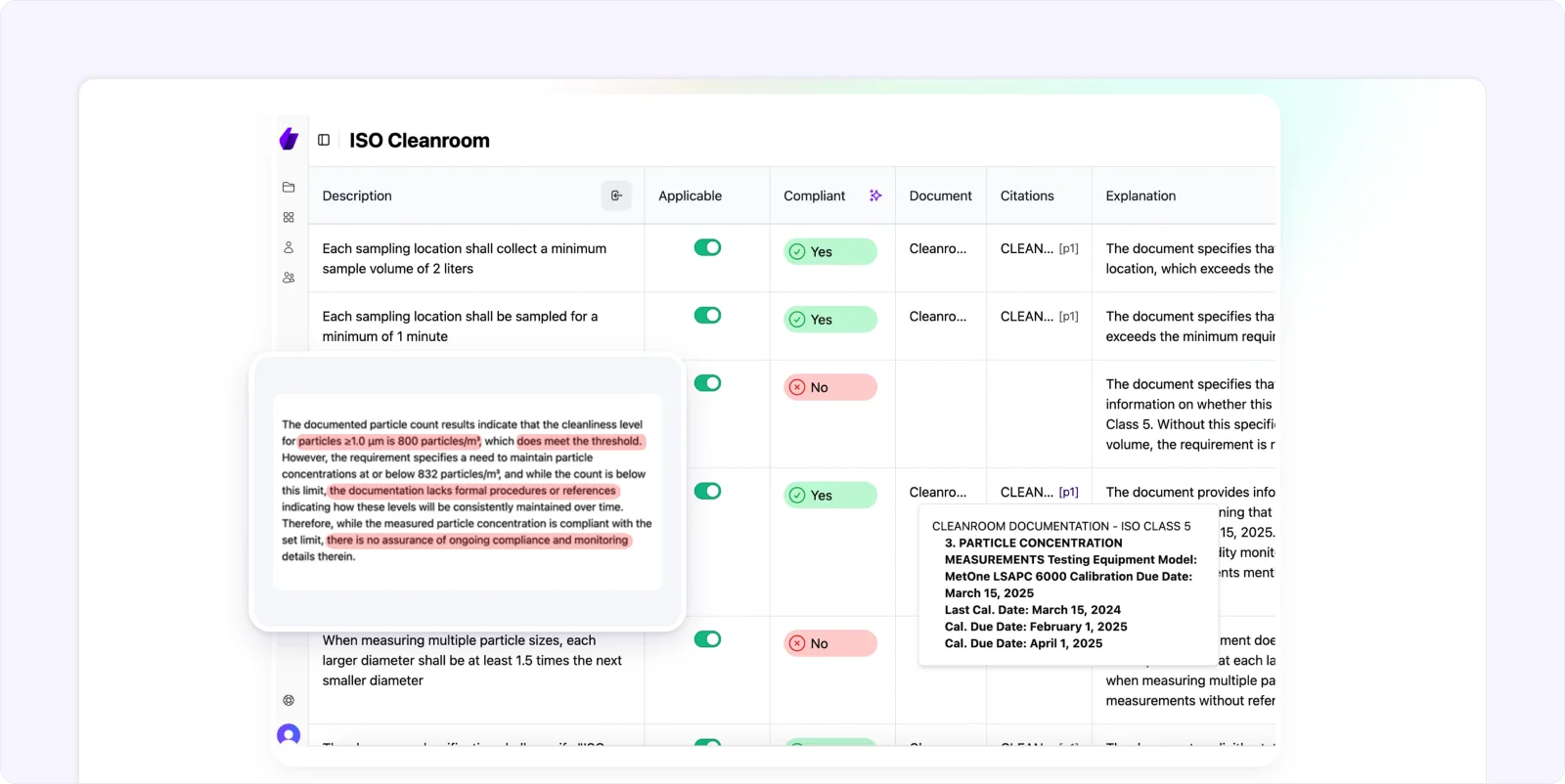

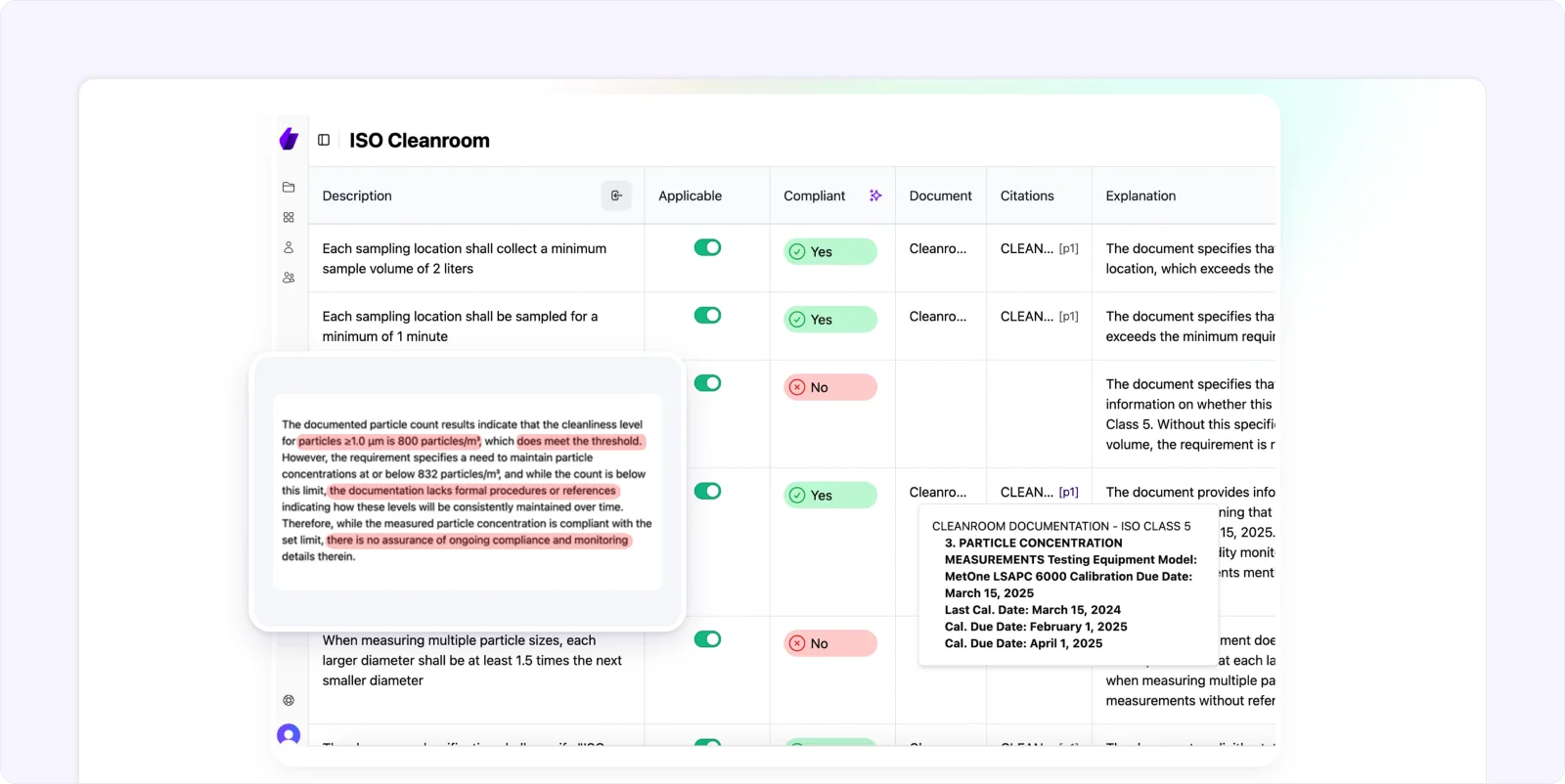

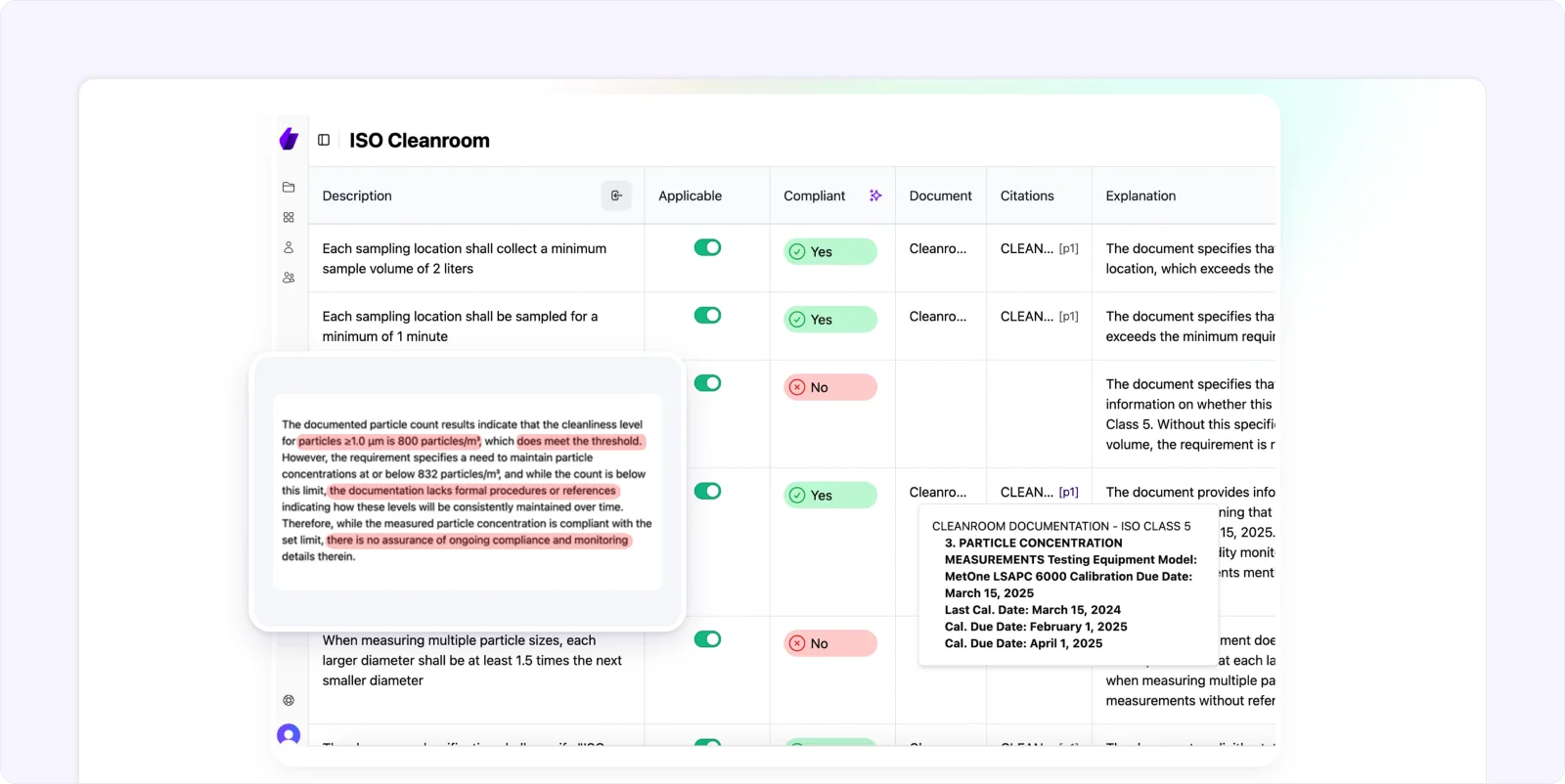

8. Validate Artwork for Accuracy and Compliance

A well-structured artwork approval process ensures that packaging designs meet compliance standards and are error-free.

This step is crucial for maintaining consistency and preventing mistakes that could result in costly product recalls.

➤ Why it matters: This process minimizes the risk of costly mistakes or delays due to non-compliance.

➤ How to implement:

Implement a workflow that allows legal, marketing, and regulatory teams to review all packaging designs.

Utilize digital tools to track artwork versions, ensuring compliance with standards such as FDA 21 CFR Part 11 and EU Annex 11.

Pro tip

Signify allows you to validate product labeling with precision by automatically inspecting artwork, packaging, and labels against applicable regulatory requirements.

This helps identify compliance gaps early in the design process, reducing costly revisions and ensuring that your labels are compliant before they reach the market.

Sustainability

By focusing on sustainability, brands can meet consumer demand for eco-friendly products while also complying with global environmental regulations.

Here is how you can do it.

9. Use Eco-Friendly Materials

Eco-friendly materials reduce the environmental footprint of packaging while meeting the growing demand for sustainable products.

Using recycled or biodegradable materials can position your brand as environmentally responsible.

➤ Why it matters: They contribute to meeting global sustainability goals.

➤ How to implement:

Utilize materials such as recycled paperboard, bioplastics, or plant-based alternatives in your packaging design to reduce environmental impact.

Opt for single-material designs to simplify recycling processes and minimize waste.

10. Right-Size Packaging to Reduce Waste

Minimalism and right-sizing packaging help eliminate excess material usage, reducing waste and ensuring packaging is as efficient as possible.

This practice also complies with regulations aimed at minimizing packaging size and weight.

➤ Why it matters: It meets regulations that mandate packaging be compact and efficient, while also improving the overall consumer experience.

➤ How to implement:

Design packaging to utilize only the necessary materials for protection, avoiding excess padding and oversized boxes.

Follow regulations such as the EU Packaging Regulation, which requires packaging to be as small and lightweight as possible.

11. Source Materials from Sustainable Suppliers

A sustainable supply chain involves sourcing materials responsibly and minimizing environmental impact at every step.

This approach contributes to a more circular economy and meets regulatory standards.

➤ Why it matters: This aligns with regulatory trends towards more sustainable practices.

➤ How to implement:

Source materials from certified suppliers who use responsible practices, such as FSC-certified paper and non-toxic inks.

Be prepared for Extended Producer Responsibility (EPR) regulations by tracking the material types and recyclability of your products.

Industry-Specific Product Packaging Examples (2024–2025)

The following examples show how different industries are adapting their packaging to meet regulatory requirements, consumer expectations, and sustainability goals in 2024–2025:

➤ Food & Beverage (US/EU):

Impossible Foods’ 2024 redesign featured bold red packaging to appeal to meat-eaters.

This shift helped the brand convey a stronger meaty flavor profile, attracting a wider audience beyond plant-based consumers.

➤ Cosmetics & Personal Care:

Glossier's 2024 minimalist design, featuring sleek pink and white packaging, reinforced its modern, clean brand image.

This change helped elevate the brand's appeal, particularly in the competitive beauty market, making it more recognizable and on-trend.

➤ Pharmaceuticals & Medical Devices: Pharmaceutical packaging now includes 2D barcodes for authentication, as seen in the EU’s Falsified Medicines Directive.

This update enhanced product traceability and security, thereby reducing the risk of counterfeit drugs.

➤ Tobacco & Vaping Products: In the EU, cigarettes now feature large graphic health warnings covering 65% of the pack.

This redesign is designed to reduce the appeal of smoking and promote public health, while also aligning with stringent regulatory standards.

Streamline Packaging Compliance with Signify

Signify is an AI compliance agent that helps manufacturers across various industries, including food and beverage, cosmetics, pharma, tobacco, and more, ensure their packaging meets global regulatory standards quickly and accurately.

Whether you're navigating complex packaging regulations for new markets or ensuring compliance with ever-changing industry rules, Signify simplifies your packaging approval process, saving you time and reducing errors.

Some of Signify’s standout features include:

Automated Labeling Compliance: Quickly validate your product packaging and labels against global regulatory standards, ensuring you meet all requirements before going to market.

Efficient Label Element Inspection: Automate the inspection of claims, ingredient lists, allergen declarations, and formatting to ensure full regulatory compliance without manual checks.

Cost Reduction on Label Revisions: Identify non-compliant elements early in the design process, saving you from costly revisions, delays, and rework.

Artwork and Packaging Accuracy: Ensure your packaging artwork aligns with brand guidelines and regulatory standards across multiple markets, eliminating errors before production.

Automated Conformity Assessments: Use AI to review policies, procedures, and documentation, pinpointing compliance gaps in minutes rather than weeks.

Proactive Regulatory Intelligence: Stay informed with continuous updates and alerts about relevant regulatory changes that may impact your packaging.

Global Compliance Management: Consolidate packaging requirements from multiple markets into a single, streamlined process, reducing redundant efforts and simplifying compliance across regions.

Try Signify today and discover how AI-powered compliance agents can transform your packaging process, helping you stay compliant, reduce delays, and accelerate your product launches without missing a step.

In 2025, the global packaging market is projected to reach $508.37 billion, growing at a compound annual growth rate (CAGR) of 7.2%.

With this growth, the importance of effective product packaging continues to rise.

In this article, we’ll dive into 12 product packaging best practices and the role of artwork validation in ensuring packaging compliance.

Let’s begin!

What is Product Packaging and Why Is It Important?

Product packaging is the process of creating the exterior of a product to protect, contain, and present it to consumers in a visually appealing manner.

The design must also clearly convey important information, meet regulatory compliance standards, and be adaptable to different consumer needs, all while supporting sustainable practices.

➤ This includes:

Adhering to Legal Requirements: Ensure packaging meets necessary regulations for ingredient disclosures, safety warnings, and other mandatory information.

Labeling Standards: Adhere to industry-specific guidelines for clear and accurate labeling, including product information and relevant certifications.

Regulatory Compliance: Ensure packaging complies with relevant industry regulations (e.g., FDA, EMA, CLP) to avoid legal issues and ensure safety.

In addition to meeting regulatory requirements, the importance of packaging design is also reflected in the following aspects:

Brand Identity: Packaging reflects your brand’s values and personality, helping consumers recognize and connect with your product.

Protection and Preservation: It ensures the product’s safety during transport, storage, and handling, maintaining its quality.

Consumer Experience: Good design improves usability and enhances the unboxing experience, encouraging repeat purchases.

Marketing Appeal: Attractive packaging can stand out on shelves or online listings, influencing buying decisions and boosting sales.

Pro tip

To stay ahead of regulatory changes, leverage Signify's automated regulatory monitoring to monitor evolving regulations and standards that impact your products.

With real-time regulatory updates and clear, actionable insights, Signify helps you focus on the changes that matter most to your business, allowing you to adapt proactively before any changes are enforced.

Packaging Types, Levels, and Functions

Product packaging is typically categorized into three levels:

➤ Primary Packaging:

This is the immediate container that directly holds the product, representing the smallest unit of sale.

Examples include a soda bottle, cereal box, or blister pack, as well as labels on medicine vials or pet food pouches.

➤ Secondary Packaging:

This packaging groups one or more primary units together, typically for shipping, display, or marketing.

Common examples include corrugated cartons (e.g., holding six cans of soda), shrink-wrapped multipacks, and retail display boxes.

➤ Tertiary Packaging:

Used for bulk storage and transportation of multiple secondary packages, tertiary packaging includes items such as pallets, stretch wrap, and large crates.

Its primary purpose is to ensure protection and efficiency during logistics and warehousing.

Key Packaging Functions (the 3 Ps)

Packaging serves three essential functions: protection, preservation, and presentation.

Each function plays a crucial role in maintaining the product’s integrity and appealing to consumers:

Protection: Packaging must safeguard the product from physical, chemical, and biological damage during handling and shipping. Under US cGMP (FDA 21 CFR 211 Subpart G), written procedures are required for inspecting and testing all packaging materials before use.

Preservation: Packaging helps extend shelf life and maintain product quality. This includes barrier properties and moisture control.

Presentation: Packaging design visually conveys the brand and product message, drawing consumer attention with colors, graphics, typography, and shape.

12 Best Practices to Design Product Packaging

Branding and Visual Identity

Effective packaging should reflect your brand’s values, reinforce your message, and make a lasting impression.

Let’s see how you can affect it.

1. Ensure Consistency Across Packaging

Packaging consistency across all products ensures a unified brand identity that customers easily recognize and trust.

This reinforces your brand message and fosters familiarity, a key factor in achieving long-term brand success.

➤ Why it matters: Consistent branding across all packaging ensures a cohesive, recognizable identity that strengthens customer loyalty and drives brand recognition.

➤ How to implement:

Use the same brand colors, logos, and fonts across all packaging elements.

Ensure that the product name, key benefits, and company logo are clearly visible and consistently placed.

2. Organize Information with a Clear Hierarchy

Clear and well-organized packaging enables consumers to locate the most important information about the product quickly.

Prioritizing visual clarity and structure ensures that essential details are easily visible and comprehensible.

➤ Why it matters: It simplifies decision-making and improves the shopping experience.

➤ How to implement:

Organize visual elements so that key information, such as the product name and claims, are the first things consumers notice.

Keep the design minimalistic, using clean layouts and ample white space to avoid clutter.

3. Engage Consumers with Multi-Sensory Design

Multi-sensory packaging elements enhance consumer engagement by stimulating more than just the visual senses.

This creates a richer experience, allowing customers to connect emotionally and build a memorable brand interaction.

➤ Why it matters: Multi-sensory elements such as textures, scents, or interactive features deepen the connection between the product and the consumer.

➤ How to implement:

Add textures, such as embossing or soft-touch coatings, to enhance the tactile experience.

Utilize scents, such as scratch-and-sniff features, or incorporate interactive elements like QR codes to enhance the digital experience.

4. Test and Personalize Designs for Engagement

Personalized packaging and market testing enable brands to understand what resonates most with their target audience.

It enables more targeted engagement and produces packaging that genuinely appeals to the consumer.

➤ Why it matters: Testing different design variations and personalizing packaging helps brands connect with their audience on a deeper, more meaningful level.

It also boosts customer engagement and loyalty by offering a unique experience.

➤ How to implement:

Run market tests with different design variations (colors, fonts, shapes) to see which resonates best.

Use digital printing for personalized labels or limited-edition packaging that engages customers.

Compliance & Labeling

Packaging must adhere to both local and international standards to ensure safety, transparency, and proper information.

Let’s explore it further.

5. Comply with Regulatory Labeling Requirements

Regulatory content includes mandatory label elements that ensure your product complies with relevant laws and regulations.

This is especially crucial for industries such as food, cosmetics, and pharmaceuticals, where non-compliance can result in significant legal and financial repercussions.

➤ Why it matters: Accurate, compliant labeling ensures your product adheres to legal standards and helps avoid fines, recalls, or legal challenges.

➤ How to implement:

Adhere to local regulations, such as FDA guidelines in the U.S. or FIC requirements in the EU, to ensure ingredient lists, allergen warnings, and nutritional claims are accurate.

Regularly update labels to comply with evolving regulations and regional requirements.

Pro tip

Signify streamlines regulatory tracking, risk assessments, and product labeling validation across various industries.

With its AI-driven automation, Signify streamlines complex tasks, reduces compliance burdens, and ensures your processes remain precise and up-to-date with evolving global regulations.

Whether you’re in manufacturing or quality assurance, Signify enhances operational transparency, allowing you to focus on delivering quality products.

6. Display Hazard and Warning Labels Correctly

Packaging for products in regulated industries must include specific hazard and warning labels to protect consumers.

These labels help inform customers about potential risks associated with the product, particularly in the cases of pharmaceuticals, chemicals, and tobacco.

➤ Why it matters: It ensures that your product complies with legal safety requirements.

➤ How to implement:

Include required hazard symbols and safety phrases for chemicals and pharmaceuticals.

Follow tobacco-specific regulations for graphic health warnings in the United States and the European Union.

7. Localize Labels for Different Markets

Labeling must be appropriately localized to ensure it meets the legal requirements of each target market.

It should be accessible to a diverse consumer base and comply with regional laws regarding language and information.

➤ Why it matters: Besides requirements, it fosters trust with customers by providing them with clear, understandable information.

➤ How to implement:

Translate labels into the required languages for each target market, following local legal requirements.

Be mindful of language nuances and ensure all required warnings and instructions are clear.

8. Validate Artwork for Accuracy and Compliance

A well-structured artwork approval process ensures that packaging designs meet compliance standards and are error-free.

This step is crucial for maintaining consistency and preventing mistakes that could result in costly product recalls.

➤ Why it matters: This process minimizes the risk of costly mistakes or delays due to non-compliance.

➤ How to implement:

Implement a workflow that allows legal, marketing, and regulatory teams to review all packaging designs.

Utilize digital tools to track artwork versions, ensuring compliance with standards such as FDA 21 CFR Part 11 and EU Annex 11.

Pro tip

Signify allows you to validate product labeling with precision by automatically inspecting artwork, packaging, and labels against applicable regulatory requirements.

This helps identify compliance gaps early in the design process, reducing costly revisions and ensuring that your labels are compliant before they reach the market.

Sustainability

By focusing on sustainability, brands can meet consumer demand for eco-friendly products while also complying with global environmental regulations.

Here is how you can do it.

9. Use Eco-Friendly Materials

Eco-friendly materials reduce the environmental footprint of packaging while meeting the growing demand for sustainable products.

Using recycled or biodegradable materials can position your brand as environmentally responsible.

➤ Why it matters: They contribute to meeting global sustainability goals.

➤ How to implement:

Utilize materials such as recycled paperboard, bioplastics, or plant-based alternatives in your packaging design to reduce environmental impact.

Opt for single-material designs to simplify recycling processes and minimize waste.

10. Right-Size Packaging to Reduce Waste

Minimalism and right-sizing packaging help eliminate excess material usage, reducing waste and ensuring packaging is as efficient as possible.

This practice also complies with regulations aimed at minimizing packaging size and weight.

➤ Why it matters: It meets regulations that mandate packaging be compact and efficient, while also improving the overall consumer experience.

➤ How to implement:

Design packaging to utilize only the necessary materials for protection, avoiding excess padding and oversized boxes.

Follow regulations such as the EU Packaging Regulation, which requires packaging to be as small and lightweight as possible.

11. Source Materials from Sustainable Suppliers

A sustainable supply chain involves sourcing materials responsibly and minimizing environmental impact at every step.

This approach contributes to a more circular economy and meets regulatory standards.

➤ Why it matters: This aligns with regulatory trends towards more sustainable practices.

➤ How to implement:

Source materials from certified suppliers who use responsible practices, such as FSC-certified paper and non-toxic inks.

Be prepared for Extended Producer Responsibility (EPR) regulations by tracking the material types and recyclability of your products.

Industry-Specific Product Packaging Examples (2024–2025)

The following examples show how different industries are adapting their packaging to meet regulatory requirements, consumer expectations, and sustainability goals in 2024–2025:

➤ Food & Beverage (US/EU):

Impossible Foods’ 2024 redesign featured bold red packaging to appeal to meat-eaters.

This shift helped the brand convey a stronger meaty flavor profile, attracting a wider audience beyond plant-based consumers.

➤ Cosmetics & Personal Care:

Glossier's 2024 minimalist design, featuring sleek pink and white packaging, reinforced its modern, clean brand image.

This change helped elevate the brand's appeal, particularly in the competitive beauty market, making it more recognizable and on-trend.

➤ Pharmaceuticals & Medical Devices: Pharmaceutical packaging now includes 2D barcodes for authentication, as seen in the EU’s Falsified Medicines Directive.

This update enhanced product traceability and security, thereby reducing the risk of counterfeit drugs.

➤ Tobacco & Vaping Products: In the EU, cigarettes now feature large graphic health warnings covering 65% of the pack.

This redesign is designed to reduce the appeal of smoking and promote public health, while also aligning with stringent regulatory standards.

Streamline Packaging Compliance with Signify

Signify is an AI compliance agent that helps manufacturers across various industries, including food and beverage, cosmetics, pharma, tobacco, and more, ensure their packaging meets global regulatory standards quickly and accurately.

Whether you're navigating complex packaging regulations for new markets or ensuring compliance with ever-changing industry rules, Signify simplifies your packaging approval process, saving you time and reducing errors.

Some of Signify’s standout features include:

Automated Labeling Compliance: Quickly validate your product packaging and labels against global regulatory standards, ensuring you meet all requirements before going to market.

Efficient Label Element Inspection: Automate the inspection of claims, ingredient lists, allergen declarations, and formatting to ensure full regulatory compliance without manual checks.

Cost Reduction on Label Revisions: Identify non-compliant elements early in the design process, saving you from costly revisions, delays, and rework.

Artwork and Packaging Accuracy: Ensure your packaging artwork aligns with brand guidelines and regulatory standards across multiple markets, eliminating errors before production.

Automated Conformity Assessments: Use AI to review policies, procedures, and documentation, pinpointing compliance gaps in minutes rather than weeks.

Proactive Regulatory Intelligence: Stay informed with continuous updates and alerts about relevant regulatory changes that may impact your packaging.

Global Compliance Management: Consolidate packaging requirements from multiple markets into a single, streamlined process, reducing redundant efforts and simplifying compliance across regions.

Try Signify today and discover how AI-powered compliance agents can transform your packaging process, helping you stay compliant, reduce delays, and accelerate your product launches without missing a step.

In 2025, the global packaging market is projected to reach $508.37 billion, growing at a compound annual growth rate (CAGR) of 7.2%.

With this growth, the importance of effective product packaging continues to rise.

In this article, we’ll dive into 12 product packaging best practices and the role of artwork validation in ensuring packaging compliance.

Let’s begin!

What is Product Packaging and Why Is It Important?

Product packaging is the process of creating the exterior of a product to protect, contain, and present it to consumers in a visually appealing manner.

The design must also clearly convey important information, meet regulatory compliance standards, and be adaptable to different consumer needs, all while supporting sustainable practices.

➤ This includes:

Adhering to Legal Requirements: Ensure packaging meets necessary regulations for ingredient disclosures, safety warnings, and other mandatory information.

Labeling Standards: Adhere to industry-specific guidelines for clear and accurate labeling, including product information and relevant certifications.

Regulatory Compliance: Ensure packaging complies with relevant industry regulations (e.g., FDA, EMA, CLP) to avoid legal issues and ensure safety.

In addition to meeting regulatory requirements, the importance of packaging design is also reflected in the following aspects:

Brand Identity: Packaging reflects your brand’s values and personality, helping consumers recognize and connect with your product.

Protection and Preservation: It ensures the product’s safety during transport, storage, and handling, maintaining its quality.

Consumer Experience: Good design improves usability and enhances the unboxing experience, encouraging repeat purchases.

Marketing Appeal: Attractive packaging can stand out on shelves or online listings, influencing buying decisions and boosting sales.

Pro tip

To stay ahead of regulatory changes, leverage Signify's automated regulatory monitoring to monitor evolving regulations and standards that impact your products.

With real-time regulatory updates and clear, actionable insights, Signify helps you focus on the changes that matter most to your business, allowing you to adapt proactively before any changes are enforced.

Packaging Types, Levels, and Functions

Product packaging is typically categorized into three levels:

➤ Primary Packaging:

This is the immediate container that directly holds the product, representing the smallest unit of sale.

Examples include a soda bottle, cereal box, or blister pack, as well as labels on medicine vials or pet food pouches.

➤ Secondary Packaging:

This packaging groups one or more primary units together, typically for shipping, display, or marketing.

Common examples include corrugated cartons (e.g., holding six cans of soda), shrink-wrapped multipacks, and retail display boxes.

➤ Tertiary Packaging:

Used for bulk storage and transportation of multiple secondary packages, tertiary packaging includes items such as pallets, stretch wrap, and large crates.

Its primary purpose is to ensure protection and efficiency during logistics and warehousing.

Key Packaging Functions (the 3 Ps)

Packaging serves three essential functions: protection, preservation, and presentation.

Each function plays a crucial role in maintaining the product’s integrity and appealing to consumers:

Protection: Packaging must safeguard the product from physical, chemical, and biological damage during handling and shipping. Under US cGMP (FDA 21 CFR 211 Subpart G), written procedures are required for inspecting and testing all packaging materials before use.

Preservation: Packaging helps extend shelf life and maintain product quality. This includes barrier properties and moisture control.

Presentation: Packaging design visually conveys the brand and product message, drawing consumer attention with colors, graphics, typography, and shape.

12 Best Practices to Design Product Packaging

Branding and Visual Identity

Effective packaging should reflect your brand’s values, reinforce your message, and make a lasting impression.

Let’s see how you can affect it.

1. Ensure Consistency Across Packaging

Packaging consistency across all products ensures a unified brand identity that customers easily recognize and trust.

This reinforces your brand message and fosters familiarity, a key factor in achieving long-term brand success.

➤ Why it matters: Consistent branding across all packaging ensures a cohesive, recognizable identity that strengthens customer loyalty and drives brand recognition.

➤ How to implement:

Use the same brand colors, logos, and fonts across all packaging elements.

Ensure that the product name, key benefits, and company logo are clearly visible and consistently placed.

2. Organize Information with a Clear Hierarchy

Clear and well-organized packaging enables consumers to locate the most important information about the product quickly.

Prioritizing visual clarity and structure ensures that essential details are easily visible and comprehensible.

➤ Why it matters: It simplifies decision-making and improves the shopping experience.

➤ How to implement:

Organize visual elements so that key information, such as the product name and claims, are the first things consumers notice.

Keep the design minimalistic, using clean layouts and ample white space to avoid clutter.

3. Engage Consumers with Multi-Sensory Design

Multi-sensory packaging elements enhance consumer engagement by stimulating more than just the visual senses.

This creates a richer experience, allowing customers to connect emotionally and build a memorable brand interaction.

➤ Why it matters: Multi-sensory elements such as textures, scents, or interactive features deepen the connection between the product and the consumer.

➤ How to implement:

Add textures, such as embossing or soft-touch coatings, to enhance the tactile experience.

Utilize scents, such as scratch-and-sniff features, or incorporate interactive elements like QR codes to enhance the digital experience.

4. Test and Personalize Designs for Engagement

Personalized packaging and market testing enable brands to understand what resonates most with their target audience.

It enables more targeted engagement and produces packaging that genuinely appeals to the consumer.

➤ Why it matters: Testing different design variations and personalizing packaging helps brands connect with their audience on a deeper, more meaningful level.

It also boosts customer engagement and loyalty by offering a unique experience.

➤ How to implement:

Run market tests with different design variations (colors, fonts, shapes) to see which resonates best.

Use digital printing for personalized labels or limited-edition packaging that engages customers.

Compliance & Labeling

Packaging must adhere to both local and international standards to ensure safety, transparency, and proper information.

Let’s explore it further.

5. Comply with Regulatory Labeling Requirements

Regulatory content includes mandatory label elements that ensure your product complies with relevant laws and regulations.

This is especially crucial for industries such as food, cosmetics, and pharmaceuticals, where non-compliance can result in significant legal and financial repercussions.

➤ Why it matters: Accurate, compliant labeling ensures your product adheres to legal standards and helps avoid fines, recalls, or legal challenges.

➤ How to implement:

Adhere to local regulations, such as FDA guidelines in the U.S. or FIC requirements in the EU, to ensure ingredient lists, allergen warnings, and nutritional claims are accurate.

Regularly update labels to comply with evolving regulations and regional requirements.

Pro tip

Signify streamlines regulatory tracking, risk assessments, and product labeling validation across various industries.

With its AI-driven automation, Signify streamlines complex tasks, reduces compliance burdens, and ensures your processes remain precise and up-to-date with evolving global regulations.

Whether you’re in manufacturing or quality assurance, Signify enhances operational transparency, allowing you to focus on delivering quality products.

6. Display Hazard and Warning Labels Correctly

Packaging for products in regulated industries must include specific hazard and warning labels to protect consumers.

These labels help inform customers about potential risks associated with the product, particularly in the cases of pharmaceuticals, chemicals, and tobacco.

➤ Why it matters: It ensures that your product complies with legal safety requirements.

➤ How to implement:

Include required hazard symbols and safety phrases for chemicals and pharmaceuticals.

Follow tobacco-specific regulations for graphic health warnings in the United States and the European Union.

7. Localize Labels for Different Markets

Labeling must be appropriately localized to ensure it meets the legal requirements of each target market.

It should be accessible to a diverse consumer base and comply with regional laws regarding language and information.

➤ Why it matters: Besides requirements, it fosters trust with customers by providing them with clear, understandable information.

➤ How to implement:

Translate labels into the required languages for each target market, following local legal requirements.

Be mindful of language nuances and ensure all required warnings and instructions are clear.

8. Validate Artwork for Accuracy and Compliance

A well-structured artwork approval process ensures that packaging designs meet compliance standards and are error-free.

This step is crucial for maintaining consistency and preventing mistakes that could result in costly product recalls.

➤ Why it matters: This process minimizes the risk of costly mistakes or delays due to non-compliance.

➤ How to implement:

Implement a workflow that allows legal, marketing, and regulatory teams to review all packaging designs.

Utilize digital tools to track artwork versions, ensuring compliance with standards such as FDA 21 CFR Part 11 and EU Annex 11.

Pro tip

Signify allows you to validate product labeling with precision by automatically inspecting artwork, packaging, and labels against applicable regulatory requirements.

This helps identify compliance gaps early in the design process, reducing costly revisions and ensuring that your labels are compliant before they reach the market.

Sustainability

By focusing on sustainability, brands can meet consumer demand for eco-friendly products while also complying with global environmental regulations.

Here is how you can do it.

9. Use Eco-Friendly Materials

Eco-friendly materials reduce the environmental footprint of packaging while meeting the growing demand for sustainable products.

Using recycled or biodegradable materials can position your brand as environmentally responsible.

➤ Why it matters: They contribute to meeting global sustainability goals.

➤ How to implement:

Utilize materials such as recycled paperboard, bioplastics, or plant-based alternatives in your packaging design to reduce environmental impact.

Opt for single-material designs to simplify recycling processes and minimize waste.

10. Right-Size Packaging to Reduce Waste

Minimalism and right-sizing packaging help eliminate excess material usage, reducing waste and ensuring packaging is as efficient as possible.

This practice also complies with regulations aimed at minimizing packaging size and weight.

➤ Why it matters: It meets regulations that mandate packaging be compact and efficient, while also improving the overall consumer experience.

➤ How to implement:

Design packaging to utilize only the necessary materials for protection, avoiding excess padding and oversized boxes.

Follow regulations such as the EU Packaging Regulation, which requires packaging to be as small and lightweight as possible.

11. Source Materials from Sustainable Suppliers

A sustainable supply chain involves sourcing materials responsibly and minimizing environmental impact at every step.

This approach contributes to a more circular economy and meets regulatory standards.

➤ Why it matters: This aligns with regulatory trends towards more sustainable practices.

➤ How to implement:

Source materials from certified suppliers who use responsible practices, such as FSC-certified paper and non-toxic inks.

Be prepared for Extended Producer Responsibility (EPR) regulations by tracking the material types and recyclability of your products.

Industry-Specific Product Packaging Examples (2024–2025)

The following examples show how different industries are adapting their packaging to meet regulatory requirements, consumer expectations, and sustainability goals in 2024–2025:

➤ Food & Beverage (US/EU):

Impossible Foods’ 2024 redesign featured bold red packaging to appeal to meat-eaters.

This shift helped the brand convey a stronger meaty flavor profile, attracting a wider audience beyond plant-based consumers.

➤ Cosmetics & Personal Care:

Glossier's 2024 minimalist design, featuring sleek pink and white packaging, reinforced its modern, clean brand image.

This change helped elevate the brand's appeal, particularly in the competitive beauty market, making it more recognizable and on-trend.

➤ Pharmaceuticals & Medical Devices: Pharmaceutical packaging now includes 2D barcodes for authentication, as seen in the EU’s Falsified Medicines Directive.

This update enhanced product traceability and security, thereby reducing the risk of counterfeit drugs.

➤ Tobacco & Vaping Products: In the EU, cigarettes now feature large graphic health warnings covering 65% of the pack.

This redesign is designed to reduce the appeal of smoking and promote public health, while also aligning with stringent regulatory standards.

Streamline Packaging Compliance with Signify

Signify is an AI compliance agent that helps manufacturers across various industries, including food and beverage, cosmetics, pharma, tobacco, and more, ensure their packaging meets global regulatory standards quickly and accurately.

Whether you're navigating complex packaging regulations for new markets or ensuring compliance with ever-changing industry rules, Signify simplifies your packaging approval process, saving you time and reducing errors.

Some of Signify’s standout features include:

Automated Labeling Compliance: Quickly validate your product packaging and labels against global regulatory standards, ensuring you meet all requirements before going to market.

Efficient Label Element Inspection: Automate the inspection of claims, ingredient lists, allergen declarations, and formatting to ensure full regulatory compliance without manual checks.

Cost Reduction on Label Revisions: Identify non-compliant elements early in the design process, saving you from costly revisions, delays, and rework.

Artwork and Packaging Accuracy: Ensure your packaging artwork aligns with brand guidelines and regulatory standards across multiple markets, eliminating errors before production.

Automated Conformity Assessments: Use AI to review policies, procedures, and documentation, pinpointing compliance gaps in minutes rather than weeks.

Proactive Regulatory Intelligence: Stay informed with continuous updates and alerts about relevant regulatory changes that may impact your packaging.

Global Compliance Management: Consolidate packaging requirements from multiple markets into a single, streamlined process, reducing redundant efforts and simplifying compliance across regions.

Try Signify today and discover how AI-powered compliance agents can transform your packaging process, helping you stay compliant, reduce delays, and accelerate your product launches without missing a step.

The information presented is for educational and informational purposes only and should not be construed as legal, regulatory, or professional advice. Organizations should consult with qualified legal and compliance professionals for guidance specific to their circumstances.

12 Best Practices to Design Product Packaging [+Pro Tips]

12 Best Practices to Design Product Packaging [+Pro Tips]

Jun 12, 2025